Toyota's Twincams

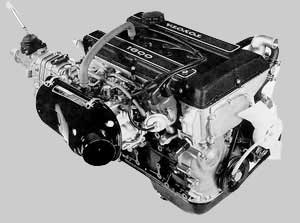

Toyota built their formidable Twin Cam reputation on these engines. Based on the popular T block and R block of the early 70's, these engines were the envy of all car manufacturers. These engines evolved- from the early stock ohv and sohc variety to the pure high performance G models, then the smog controlled models, and finally the fuel injected and turbo models. Originally the 2TG (1588cc) started at 115 HP, and the 18RG (1968cc) at 145 HP. Both engines had a twin- the 2TGR and 18RGR which had low compression pistons, but identical cylinder heads. In the mid 70's both the 2TGU and 18RGU saw a further drop in compression, emission controlled carburetors, and shorter duration camshafts. However, the heads were upgraded with bigger valves and hardened valve seats (for unleaded fuel). Horsepower figures typically dropped about 10/15 HP. By the late 70's, the fuel injected models arrived as the 2TGEU and 18RGEU, to regain all the lost horsepower. These models, despite still shorter duration cams and lower compression, had the best cylinder heads with still bigger valves.

The 3TGTE (1770cc) replaced both engines by 1983. The well-proven head design- now had 2 spark plugs per cylinder and a turbocharger to develop 160 HP. Despite claims of Toyota that the 503 race engine was based on the 3SG design- the bottom end was patterned after the 3T block (which had become wider in the lower block skirt to accommodate the longer stroke crankshaft. The crankshaft saddles are identical!

The competition models of the 2TG and 18RG, developed with parts from TRD saw many worldwide wins for Toyota- Corolla Levins, Sprinter Truenos, and Celica 1600 GTs with the 2TGs. In Asian and European Formula racing, the 2TG in the 1600cc category regularly beat all the other engine manufacturers. The Celica 2000 GTs saw many race and rally victories worldwide, including the European based WRC (World Rally Cup).

In the ultimate WRC Group B series, "the super class" in the World Rally Cup- the 4TGTE (homologation model of the 3TGTE) powered the Celicas of Toyota Team Europe to the Championship. The Group B class was soon cancelled after the general public and some rally entrants protested that the cars were unsafe because of the powerful engines.

The ultimate versions of the 2TG and 18RG were the 151E and 152E. These were not production engines. The heads and blocks were not interchangeable to the production units. (These heads were the design forerunners of the 503E heads.) Both engines had 4-valves per cylinder with either carburetors or mechanical fuel injection. These racing heads were fitted on heavily modified T and R blocks- basically to accommodate the new heads' chain set-up (for the fuel injection and the dry sump oiling system). Originally they came in the same 1588cc and 1968cc configuration that were targeted to the specific 1600 and 2000 classifications for FIA (Federacion Internationale Automobile) regulations. For the U.S. IMSA (International Motorsport Association) the 152E was bored to 2200 to qualify in the "under 2.5 class"- normally aspirated at 330 HP.

The first race engine based on the 2TG was made by TMC (Toyota Motor Corporation) in 1970 and was known as the 100E. Toyota built about 25 engines with full racing specifications- specially casted head (11111-______) yes, blank numbers!, special intake manifolds, dry-sump oil system, 50mm Mikunis, ND igniter and instrumentation, ND fuel pump and some other trick stuff. Of the 25 engines- 8 went into Corollas (Levin and Trueno), 10 went into Celicas, and the rest were spares. Eventually TOSCO (Toyota Sports Corner) was organized and some parts from this project became available individually. TOSCO later became TRD.

The success of these engines has been greatest in the streets. The Celicas with built 18RG could outrun the 240Zs and Skylines, of that generation. The Levins and Truenos with prepared 2TGs outran all Japanese models and all European Twin Cam models- the Alfa-Romeos, Lancias, including the Lotus Cortinas and Escort Cosworths (of the 16-valve BDA variety. The Toyota Twin Cams was regarded highly by all competitors. It was the envy of the other manufacturer tuners. Some tuners in European formula racing made valve covers with their corporate names, to hide the Toyota origin.

MODIFIYING THE 2TG AND 18RG

The 2TG and 18RG, in all the different varieties- offer immense tuning combinations.

Block: The 2TG blocks were similar to the 2T and 3T blocks of the same year generation. For modification purposes the 3T block is preferred because it has the longer stroke crank, and with a bore-up to 89mm becomes a 2000cc. The later model 2TGEU block is the same as the 3T, and will take the 3T crank with no modifications. The 2TG stock block can be bored to 1750cc, with a similar bore-up to 89mm. To fit the 3T crank in an original 2TG block can be done with a lot of work- grinding the inside of the block skirts to clear the rods. The 2T and 3T cranks are forged. There is also available a 2150cc. using a modified Toyota 4Y crankshaft. The 4Y crank is not forged, but there is an aftermarket steel billet unit. In converting a single cam block to a twin cam, aside from switching over all the front valve train components, the original cam bearings have to be turned and repositioned. You must have a complete donor Twin Cam to do the conversion. Installing the 2TG into any T engined Corolla is a bolt-in deal with no modifications to the crossmember or brackets.

The 18RG block can be bored to 2200cc (92mm) or stroked to 2400cc (using a modified 20/22R crank). No the 18RG head will not bolt on a 20R/22R block! The stroker crank is not recommended. Aside from the very expensive to modify to fit the 18RG block, it seriously cuts into the revving characteristic of the Twin Cam. The 18R blocks did not change that much, but installing into the later model pick-up and Celica will need the newer block that have the extra engine support holes embossed on the sides of the block. Because of the wider variety of models the engines originally came in, there are 4 different oil pans, six different engine brackets. Fitting into specific applications will be a matter of matching the oil pan configuration to the original engine; and the engine brackets to the width of the crossmember. On the older Celicas with the 18R engine- it is a bolt on by using the pan and brackets off the original engine.

Cylinder Head: The early generation 2TG and 18RG heads had the best camshaft profiles and carburetors. They will respond extremely well to porting and big valves. If the block is bored out or the compression raised, longer duration cams will be needed. The mid-generation 2TGU and 18RGU heads had bigger valves, hardened seats, lower duration cams, and problematic carburetors. This is the head to use for turbocharged applications- since the head can be used with the original cams with the hardened valve seals and the (piston) compression is lower. The 2TGEU and 18RGEU had the reinforced heads, bigger valves, and the lowest compression (pistons). The EFI intake can be retrofitted back to carburetors.

The Twin Cam head must only be machined by experienced machine shops. Valve service and installation is very critical. If not properly machined there will be a problem adjusting the shims, valve spring tension, and camshaft timing adjustment. The head must not be surfaced more than 1 mm or .040 in. Please read notes under Recommended Set-ups / Race configuration!

Fuel System: The best performance can be achieved by using Fuel Injection over the carburetors. The standard Toyota ECUs are in short supply, but the most reliable set-up. For the EGU engines- the early 4AG Corolla GTS and MR2 computers can be used, since they operate within the same rpm range. Programmable Fuel Management systems will allow high compression, and radical cams- even turbo. Carburated motors will need Mikunis or Webers- if the stock Mikuni-Solex are not serviceable or to up-grade the GU carbs. For bored-out 18RGs the minimum carburetor size is at least a 44, and 40s will be sufficient for the 2TG up to 2000cc. The chokes must be changed to match the displacement. Turbocharging through carburetors is limited to about 10 psi using a fuel pressure-adjusting regulator. Do not rely on the Toyota mechanical or electric pump- use a low pressure, high volume pump.

Ignition System: The latest generation 2TGEU and 18RGEU use a breakerless distributor. Older units can be up-graded using original Toyota distributor components from later models. Ignition amplifiers and knock sensors must be used to avoid high RPM misfires and detonation. Wire sets that have the original configuration are the best to use- they keep dirt out of the deep sparkplug pockets that may enter the block when the plugs are serviced.

Some Recommended Set-ups:

For Stock configuration- the early model 2TG and 18RG will give the best performance. Update the heads for unleaded fuel. This is ideal for vintage restorations. The 2TGU and 18RGU are also good, but change the carburetors and remove the exhaust air recirculating system. The 2TGEU and 18RGEU can be run with the early Toyota 4AG computers and will be excellent low maintenance fuel injection systems. Since these are high performance engines- assembly specifications are different from the regular variety Toyota single cams. Do not attempt to overhaul without the correct 2TG or 18RG manual! There have been a lot of heads and complete engines destroyed- when an important Twin Cam detail was overlooked even by "expert" Toyota mechanic. Set-up properly these engines will last a long time- like any Toyota engine.

For Modified configuration- Prepare the head with big valves and a good port and polish job, this is the best modification that can be done. The blocks can be bored to 1750cc (2TG) and 2200cc (18RG) without changing crankshafts. The 3T crank can be used in the 2TG to give 2000cc. Avoid stroking both engines beyond these, the loss of RPM capability and inherent internal imbalance are not worth the power gain. Anytime high compression pistons are used- the cams must be replaced to avoid extremely high cylinder pressures- that will call for retarded ignition timing (and a loss of RPM and HP). The stock carburetors should be changed to at least Mikuni 44s or Weber 45s.

For Race configuration- Treat the head to a competition port and polish with the most aggressive cams usable. You may need a custom intake manifold because stock manifolds will be the limiting factor to the port job. The big valves and dual valve springs are mandatory (they are bigger than the largest stock valves). The crankshaft and rods must be prepped- stress reliefed, heat treated, line-bored. Optionally rods may be upgraded to Carillos. Piston clearance is critical since these are high revving engines, follow the piston manufacturers tolerances. Piston valve pockets must also match the camshaft and valves used. The oil pumps in the 2TG and 18RG are different from the single cam models, try to use the original Twin Cam pumps, specially when converting to the 3T block. If available the TRD oil pumps must be used for the 2000cc 2TG. The oil pan has to baffled, specially for race and rally use. For the Full Race set-up use 320 intake and 304 cams. For the Rally set-up use 304 /288 or 304/272 cams. For the Street racer, the 304/304 set-up is very streetable and have a nice mild lobe at idle. It is very discrete! These cams cannot be used with stock pistons!! (The 288/272 cam set-up maybe used with stock pistons, as long as the head has not been cut.) Naturally adjustable gears are needed for the cams.

The fastest 2TG set-up we have done used 330/310 cams with 1750cc pistons. The fastest 18RG used 320/304 cams with 2200cc pistons. If you need a 2-liter engine, use the 2TG (it is lighter and has slightly better Connecting Rod / Stroke geometry. The 18RG will ultimately produce more HP and torque. The Twin Cam engines will respond to tuning like real race engines. Cam timing, ignition, compression ratios, exhaust design, port profiles- all have their own advantages and disadvantages. The most popular set-ups are the 2000cc 2TG and 2200cc 18RG with all camshaft combinations. There are proprietary set-ups that may be used but try these recommendations first. Do not forget water treatment as these aluminum heads will corrode fast- and there are not enough of them left.

If you have a RWD Toyota- these are the ultimate engines to upgrade to. All the popular cars had them as factory options! The late model 16 valves- aside from the 4AG which at one point was available in RWD, are almost impossible to convert because of they were installed at an angle, although we have conversion kits!

Note: The 3TGTE will respond to tuning also. Since it is a turbo- all the turbo tricks will give more power than internal work- aside from the mandatory forged pistons.