Even if you buy aftermarket heads and matching intake manifolds they will never

line up perfectly with the gasket. I was using a Edelbrock knock-off air gap intake

which was bound to require port matching - but don't be fooled into thinking that

your edelbrock intake doesn't require port matching. Basically, the idea is to make the

transition from intake / gasket / head as smooth as possible.

I used some cheap poster paint and smeared it around your intake. Another idea

is to break open a ballpoint pen and use the ink out of that. But poster paint is

easier to clean off.

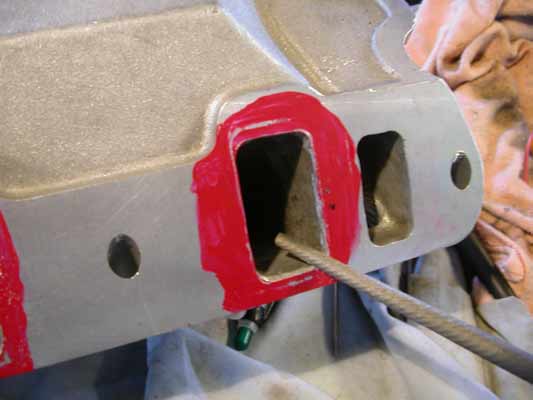

Once the head is smeared with paint you have to be quick before it dries. Place your

gaskets on the face of the heads.

Sit the intake on.. a V8 is a pain cos you have to lower the intake down evenly

making sure not to bump the gaksets.. a 4 or straight 6 would be easy. You will

need to bolt it down properly to get it sitting right. Then leave it for a while for the

paint to dry. Poster paint dries pretty quick.

Then unbolt and pull the intake off again. The gaskets will come with it and you can

see where the metal edges are that will need to be smoothed out to the gasket edge.

|

|

Some ports were worse than others but overall not too bad. It's debatable

what the gains are from doing this but hey - it's free power right? And what

else would you want to do with a sunny afternoon than sit alone in the garage

endlessly porting a intake?

While the gasket is still on I got a sharp object and carefully scribed around the

gasket port so that when I removed it there was a defined line. This is where

the intake will be ported out too. The knock-off edelbrock intake was pretty good.

There was plenty of metal there to work with. You need to be careful with some

intakes not to go too far and file into the water jacket.

I was going to use my dremil but it broke.. so it was old fashioned filing time.

I actually found the file to be better anyway, it made short work or the alloy

and was easier to work with.

Working the corners out first with the round file and then between them with the

flat file making sure to work the angles to get a smooth flow. It took a while

to do all eight ports.. but its worth it just to know that they now flow smoothly

into the head with no obstructions. You can do the paint trick again to check your

job before the intake gets bolted on.

.jpg)